As part of Intel's internal reorganization, the company separated its chip manufacturing facilities into Intel Foundry and the rest into Intel Products and filed a Form 8-K with the US Securities and Exchange Commission. The document reveals the full picture of how well Foundry Services performed: operating loss for 2023 was $7 billion, more than $2 billion worse than the previous year, and it is clear that Intel has a lot of work to do to turn this around.

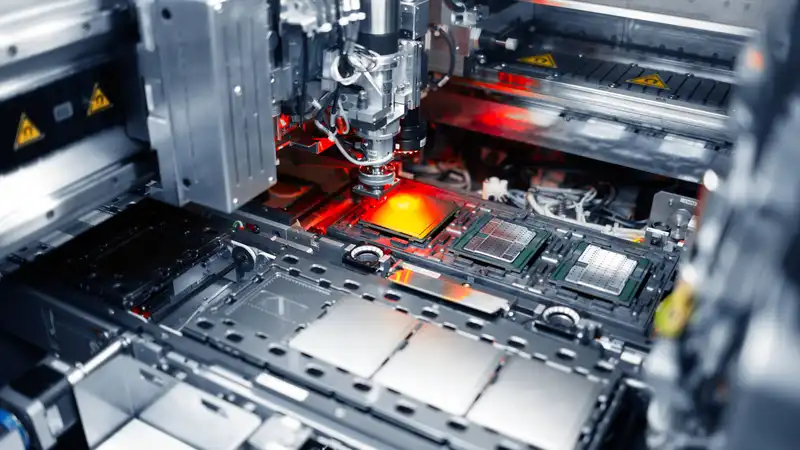

Intel CEO Pat Gelsinger explained the details during the earnings call (transcript via SeekingAlpha) and said that one of the critical mistakes Intel made was that all of its latest CPUs and GPUs are being manufactured with EUV (Extreme Ultraviolet) lithography, which He noted that it took too long to make the switch. Although Gelsinger did not mention it, Intel's foundries have traditionally only manufactured chips for their own use, and without orders from a wide range of fabless companies like AMD and Nvidia, there was little need for the company to innovate or maintain its old production lines. The company's business model is not a simple one.

TSMC and Samsung are not only pouring billions of dollars into building state-of-the-art manufacturing plants, but also keeping foundries running on older process nodes. They are not only spending billions of dollars to build state-of-the-art manufacturing plants, but they are also keeping their old process node foundries alive.

According to the 8-K, the Intel Products division is doing very well, and at the earnings call, CFO David Zinsner stated that operating margins are consistently high despite declining revenues. Intel's long-term targets for gross and operating margins are 60% and 40%, respectively.

However, due to losses across the board at Intel Foundry, the targets are much more modest at 40% gross margin and 30% operating margin by 2030. Currently, Intel aims to break even in this sector by 2027. Hence, Intel is receiving billions of dollars in funding to ensure that its multi-process node plan meets its deadlines and produces sufficient quantities of chips.

Gelsinger confirmed this during the conference call, saying, "We'll start launching Intel 3 in '25; we'll launch 18A in '26; we'll launch 18A in '27. And once we get to 18A, we believe we will have a competitive and cost structure."

Making Intel Foundry a TSMC/Samsung-like business is no mean feat. Not only is it important to invest enough to do so, but also to provide the same tools, resources, and services as their competitors; if they have spent nearly 50 years making chips almost entirely on their own, they would not need to make even basic documentation widely accessible and set certain standards.

Intel hopes that the changes it is making with its foundries will reduce its reliance on TSMC for wafers. Currently, approximately 30% of Intel's wafer needs are manufactured externally, but according to Gelsinger, Intel hopes to reduce this to 20% over time. It is unclear exactly how long this will take, but they hope to achieve this by 2030 at the latest.

The complete separation of the foundry into almost a separate company is a shrewd decision, because, as AMD showed many years ago, it is relatively easy to sell off if things go bad and money starts to dry up. If that were to happen, there would be almost nothing to stop TSMC and Samsung from dominating the chip manufacturing industry.

However, Intel has managed to secure a healthy amount of cash in the form of grants and loans through the US Chips Act. No administration will be willing to hand over billions of dollars without collateral from Intel or the US government. If all goes according to plan, Intel could dethrone Samsung and become the world's second-largest chip supplier.

Comments