A key Intel executive recently admitted that the company is relying more heavily on third-party manufacturing than it would like. For Intel, which has always prided itself on manufacturing everything it sells in-house, the prospect that its entire next Arrow Lake generation of CPUs may be manufactured at TSMC rather than in Intel factories will be a source of internal frustration.

Intel's CFO spoke on a conference call with investment bank Morgan Stanley about the chip giant's situation at the foundry, its market share, and what happens next.When asked about the relationship with TSMC, the CFO said that despite being a competitor, everything is great, but he said that Intel relies too much on outside foundries in its chip manufacturing operations compared to its own.

Morgan Stanley and David Zinser, Intel's CFO, recently discussed (via Seeking Alpha) Intel's current state, status, and near-term outlook regarding chip manufacturing.

One of the topics that received a lot of attention was the reliance on TSMC for manufacturing operations, with Zinser remarking, "Probably a little heavier than we would like in terms of external wafer manufacturing versus internal wafer manufacturing, but we are always going to use external foundries for wafers."

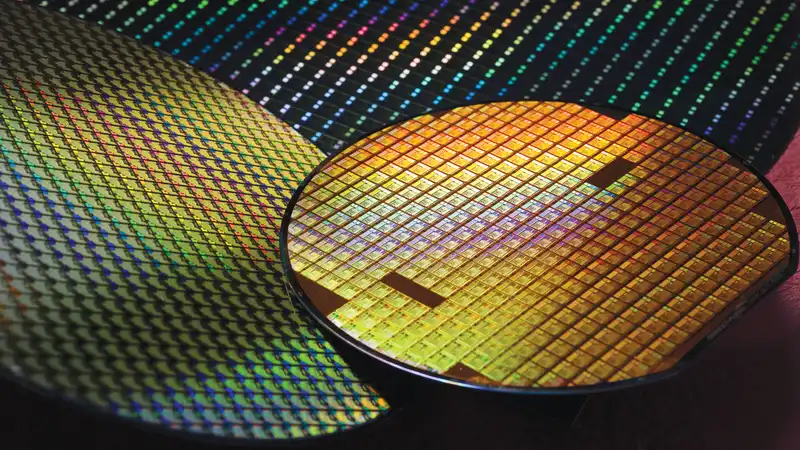

TSMC is one of the largest semiconductor companies in the world, and its chip fabrication plants (aka foundries) produce more chunks of silicon than any other company TSMC is one of the largest semiconductor companies in the world, and its chip fabrication plants (aka foundries) produce more Its chip foundries produce more blocks of silicon than any other company. TSMC's order book for the highest process node, the name given to the entire chip manufacturing order, is dominated by AMD, Apple, Nvidia, and Qualcomm, but Intel also relies on TSMC for the majority of its key chips.

For example, the GPUs used in Arc graphics cards and the huge data center processors are all made by TSMC. But so are most of the tiles in the current Meteor Lake-powered Core Ultra laptop chips, and the next generation of desktop CPUs. Intel is steadily moving toward a situation where the majority of CPUs are made up of multiple tiles (or chiplets) rather than a single block of silicon.

If you take the Core Ultra 7 155H apart, you will see four tiles nestled on top of the interposer. Only the latter and the primary compute tile, which includes all P-cores and most E-cores, are made by Intel. The chip giant is therefore making significant advances in foundry technology, and much is expected of the soon-to-be-available 18A process node.

The remaining tiles (graphics, SoC, IO) are all manufactured by TSMC, but at various TSMC foundries. [Some rumors suggest that even some of the compute tiles for the Arrow Lake chips will be manufactured by manufacturers outside of Intel and not in their own ultra-special new process nodes.

These are the next generation GPU and CPU architectures that Intel is targeting to release at some point this year, and given that Intel plans not only to maintain its share of the CPU industry, but to expand it if possible, especially in GPUs and TSMC's order book is likely to be full for some time to come.

It wasn't that long ago that Intel manufactured everything it sold, but how times have changed. Not only is TSMC heavily dependent on TSMC for the majority of consumer grade CPUs and GPUs, but they are also moving to other manufacturers for other companies. This means that while Intel is an increasingly important customer for TSMC, it is also a competitor in the foundry business.

Zinsser also admits that Intel "has fallen back because they missed the boat on EUV. Extreme ultraviolet (EUV) is a type of electromagnetic radiation used in advanced process nodes. For example, TSMC uses EUV for all nodes from N7+ onward. Of course, all of these nodes are heavily used by AMD, Apple, Nvidia, and Intel.

Intel must be feeling bitter about the delay in EUV adoption in their foundries and the fact that it is part of the reason they have to rely so heavily on TSMC and will have to continue doing so for some time yet. But the important thing for end users is that this somewhat unusual customer/competitor relationship will ultimately result in fast, affordable CPUs and GPUs.

.

Comments