We are all aware at this point that e-waste is a major problem. The numbers of how much e-waste is generated annually are staggering, with mountains of hard drives being wasted unnecessarily each year simply because they are not scattered across our floors.

But instead of watching the piles of e-waste grow, some companies are doing something about it. They are recycling electronic components, an underutilized resource of rare earths. And, of course, there is the possibility of changing materials altogether.

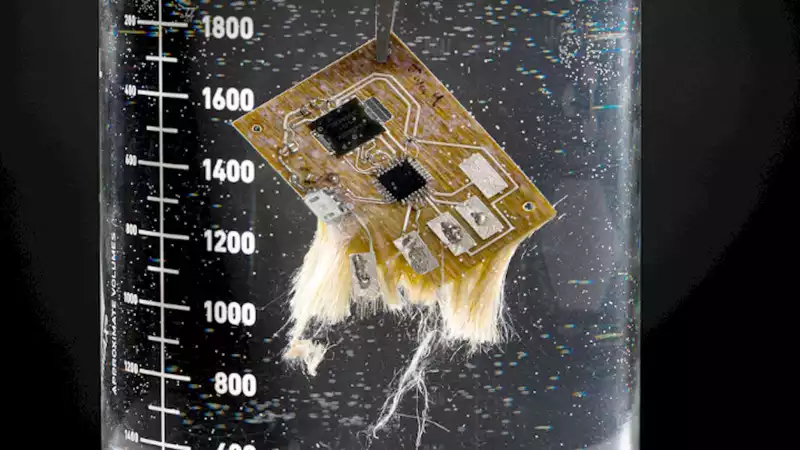

Rather than coming up with new fixes after the fact, semiconductor manufacturer Infineon Technologies AG is going back to the source itself and using a plant-based PCB design known as Soluboard. Designed by British startup Jiva Materials, this eco-friendly substrate not only has a "significantly lower carbon footprint than traditional fiberglass," but is also water soluble (via ComputerBase).

The company is researching new ways to tackle electronic waste without losing valuable materials, in accordance with the European Commission's Green Deal circular economy and WEEE (Waste Electrical and Electronic Equipment) directive. The beauty of this design is that when these boards are dissolved in water, they not only decompose, but other valuable components disappear into the ether.

"By employing a water-based recycling process, we can recover valuable metals more efficiently," says Jonathan Swanston, CEO and co-founder of Jiva Materials. [More specifically, it saves 10.5 kg of carbon and 620 g of plastic per square meter of PCB. More specifically, 10.5 kg of carbon and 620 g of plastic can be saved per square meter of PCB.

Jiva is currently working with several unnamed companies to produce an advanced beta prototype of this substrate, but its simplicity and reusability make it likely to be adopted by major high-tech companies worldwide as we move toward a greener future.

Comments